The Best Container Loading Inspection Service for Small Companies

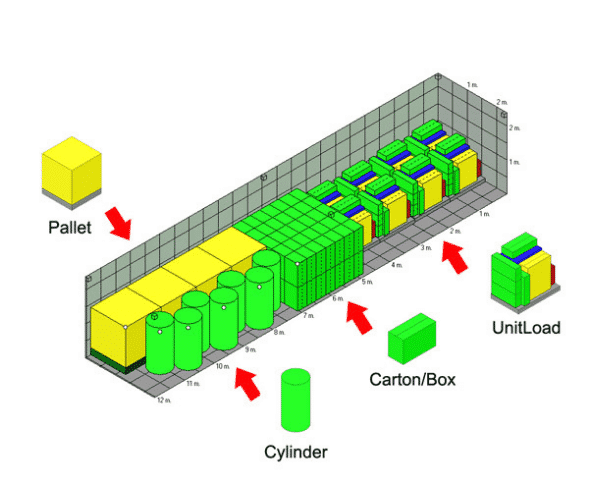

HUACI Sourcing provides container loading inspection and supervision services designed for small and medium-sized importers.

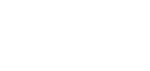

We ensure each of your containers is thoroughly checked before being loaded, and the entire loading process is under monitoring.